品牌

经销商厂商性质

上海市所在地

三丰数显高度仪518-246QMH-600BX

¥19000

三丰数显高度仪518-244QMH-350BX

¥19000

三丰高精度高度仪518-242QMH-600AX

¥19000

三丰数显测高仪518-240QMH-350AX

¥19000

三丰数显测高仪518-240/242/244/246

¥19000

三丰Mitutoyo数显测高仪518-240

¥19000

LH-600FG高精度气浮数显测高仪三丰mitutoyo

¥35000

LH-600EG高度尺升级LH-600FG测高仪

¥35000

三丰mitutoyoLH-600FG测高仪518-361-13

¥35000

三丰mitutoyoLH-600FG测高仪

¥35000

518-361-13 LH-600FG测高仪

¥35000

德国BYK4775透过率透射雾影透视清晰度仪

¥230000上海鼎徵仪器仪表设备有限公司代理销售LP-463PB-64-01 涂层附着力热冲击试验机

| 参数 | GMW15919 | Ford BI 107-05 | LP-463PB-64-01 |

| 流量 | 目标值2.7L/Min | 目标值2.7L/Min | 目标值2.7L/Min |

| 样品测试位置温度 | 98-100℃ | 98-100℃ | 98-100℃ |

| 油箱压力 | 约50psi | 约50psi | 约50psi |

| 动态压力 | 目标值37.9Kpa(5.5Psi) | 目标值37.9Kpa(5.5Psi) | 目标值37.9Kpa(5.5Psi) |

| 喷嘴和样品距离 | 50-75mm | 50-75mm | 50-75mm |

| 喷嘴和样品角度 | 45° | 45° | 45° |

| 喷嘴直径 | 12.25 to 12.75mm | 12.25 to 12.75mm | 12.25 to 12.75mm |

| 喷嘴长度 | >100mm | >100mm | >100mm |

THERMAL SHOCK PROCEDURE FOR ORGANIC COATING ADHESION TEST

涂层系统附着力测试的热冲击程序

1.0 GENERAL

Test procedure is designed to evaluate the adhesion of organic coatings.

测试程序旨在评估有机涂层的附着力。

1.1 Purpose

The purpose of this procedure is to determine the resistance to degradation and/or adhesion loss over steel, aluminum, plastic or other substrates coated with organic finishes while subjected to thermal changes and high pressure spray conditions. These conditions are similar to those generated by the heated pressure wash equipment found in manual car wash operations. Evaluation is based on a pass/fail analysis.

本程序的目的是确定在热变化和高压喷涂条件下,钢、铝、塑料或其他涂有有机涂层的基材的抗降解性和/或附着力损失性。这些情况与手动洗车操作中加热压力清洗设备产生的情况相似。评估基于通过/失败分析。

1.2 Coverage of this Standard

This test procedure may be used to evaluate organic finishes over metal or plastic substrates with

appropriate surface preparation (plating, chemical surface treatment, etc). This test procedure can be used for interior, exterior, and underhood/underbody applications.

本试验程序可用于评估金属或塑料基底上的有机饰面,包括 适当的表面处理(电镀、化学表面处理等)。本测试程序可用于车内、车外和发动机罩下/车身底部应用。

2.0 SPECIAL TEST EQUIPMENT & MATERIALS

专验设备和材料

| TABLE 1: SPECIAL TEST EQUIPMENT | ||

| Name Of Item | Description | Make/Model |

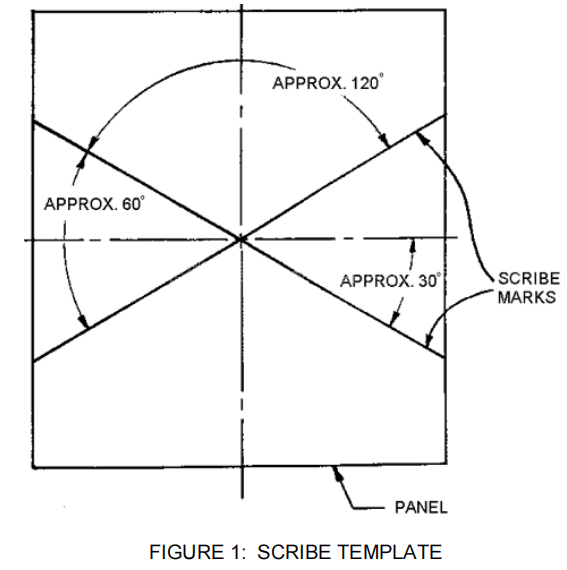

| Scribe Tool | Straight shank tungsten carbide tipped scribe device with a tip angle of 60 15 degrees or equivalent. | N.A. |

| Razor knife | Common utility knife or X-acto knife | N.A. |

| Water Bath | Capable of maintaining 38 +/- 2° C with aeration | N.A. |

| Freezer | Capable of maintaining -29 +/- 2° C N | N.A. |

| Steam Generator 蒸汽发生器 | Discharge Nozzle: 12.5 mm ID (100 mm minimum length) Dynamic Head Pressure: 37.9 +/- 2 kPa (5.5 psi) +/- 5% deviation | Model 100 Steam Generator from Atomic Steam Co., 10727 Fendell, Detroit, MI 48238 or equivalent. |

3.0 SUMMARY OF METHOD

This procedure will evaluate organic coating adhesion after exposure to elevated and reduced

temperatures using high pressure steam impingement.

本程序将评估有机涂层暴露于高温和低温环境后的附着力使用高压蒸汽冲击的温度。

4.0 SAFETY PRECAUTIONS

This test procedure involves high and low temperature conditions, steam, and high pressure spray.

Pressurized steam represents a potential burn hazard. Parts must be secured properly to the test fixture and laboratory technicians should wear full face shields and heat resistant gloves. If possible, the testing should be conducted in a test chamber equipped with a full closing front shield with safety interlock to prevent triggering steam with the shield open. This standard does not address all the safety problems associated with its use. It is the responsibility of whomever uses this standard to consult and establish appropriate safety and health practices to determine the applicability of regulatory limitations prior to use.

本试验程序涉及高温和低温条件、蒸汽和高压喷雾。加压蒸汽有潜在的烧伤危险。零件必须正确地固定在试验夹具上,实验室技术人员应佩戴全面罩和耐热手套。如有可能,应在配有全封闭前护罩(带安全联锁装置)的试验箱中进行试验,以防止护罩打开时触发蒸汽。本标准并未解决与其使用相关的所有安全问题。使用本标准的任何人都有责任在使用前咨询并建立适当的安全和健康实践,以确定监管限制的适用性。

5.0 CONDITIONING

Condition fully cured parts or panels for a minimum of 72 hours at 23 +/- 2°C and 50 +/- 10% relative humidity prior to beginning test procedure.

在开始试验程序之前,在23+/-2°C和50+/-10%相对湿度条件下对*固化的零件或面板进行至少72小时的处理。

6.0 PROCEDURE

A. Immerse test specimen in an aerated water bath at 38 2°C for 4 hours. Water should contain max 5 ppm dissolved solids as sodium chloride (NaCl).

将试样浸入38 2°C的充气水浴中4小时。水应含有最多5 ppm的溶解固体,如氯化钠(NaCl)。

B. Immediately after removal from water bath, scribe parts or panels through to the substrate as shown in Figure 1.

从水浴槽中取出后,立即将零件或面板划入基板,如所示